Currencies

Categories

- ==Bulbs By Voltage==

- 3V 5V 8V Multi voltage LED bulb (86)

- 12V low voltage led light bulbs-> (524)

- 24V 36V48V60V Multi voltage LED-> (738)

- AC 85V~265V LED light bulbs-> (483)

- AC 110V/120V LED House Lights-> (714)

- AC 220V/230V LED House Lights-> (610)

- AC100 277 LED bulb Multi voltage-> (217)

- ==Bulbs By Base==

- AR111 LED bulb QR111 G53 12V (39)

- 3 ways 2-circuit led bulb/socket (6)

- E39 led bulb hps led replacement (83)

- G4 LED bulb G5.3 LED bulb (186)

- G9 LED bulb 24V 12V 48V 110V220V (93)

- G12 LED bulb G8.5 LED lamp (55)

- G23 led bulb CFL led retrofit (60)

- G24 LED bulb 2 pin 4 pin (83)

- G6.35 GY6.35 LED bulb 12V 24V (62)

- Gu10 led bulb 12V 24V AC100-277V (158)

- GU24 LED light bulbs (12)

- GU6.5 LED bulb GU6.5 LED lamp (9)

- GX23 GX24 LED GX8.5 LED 2GX7 LED (28)

- Midget Flanged led light bulbs (26)

- Miniature LED Bulb Mini led bulb (112)

- MR11 LED bulb Mini GU4 GU10 GU11 (36)

- MR16 LED bulb GZ5.3 GU5.3 base (124)

- P28s bulb led replacement 12~24V (61)

- R7S LED bulb R7S bulb (83)

- T10 C7 T22 E12 mini led lights (42)

- LED Wardrobe lighting solutions (42)

- ==Specialty LED Bulbs==

- CFL replacement led bulbs 12V (68)

- 12v fluorescent led replacement (35)

- LED Fluorescent tube replacement-> (395)

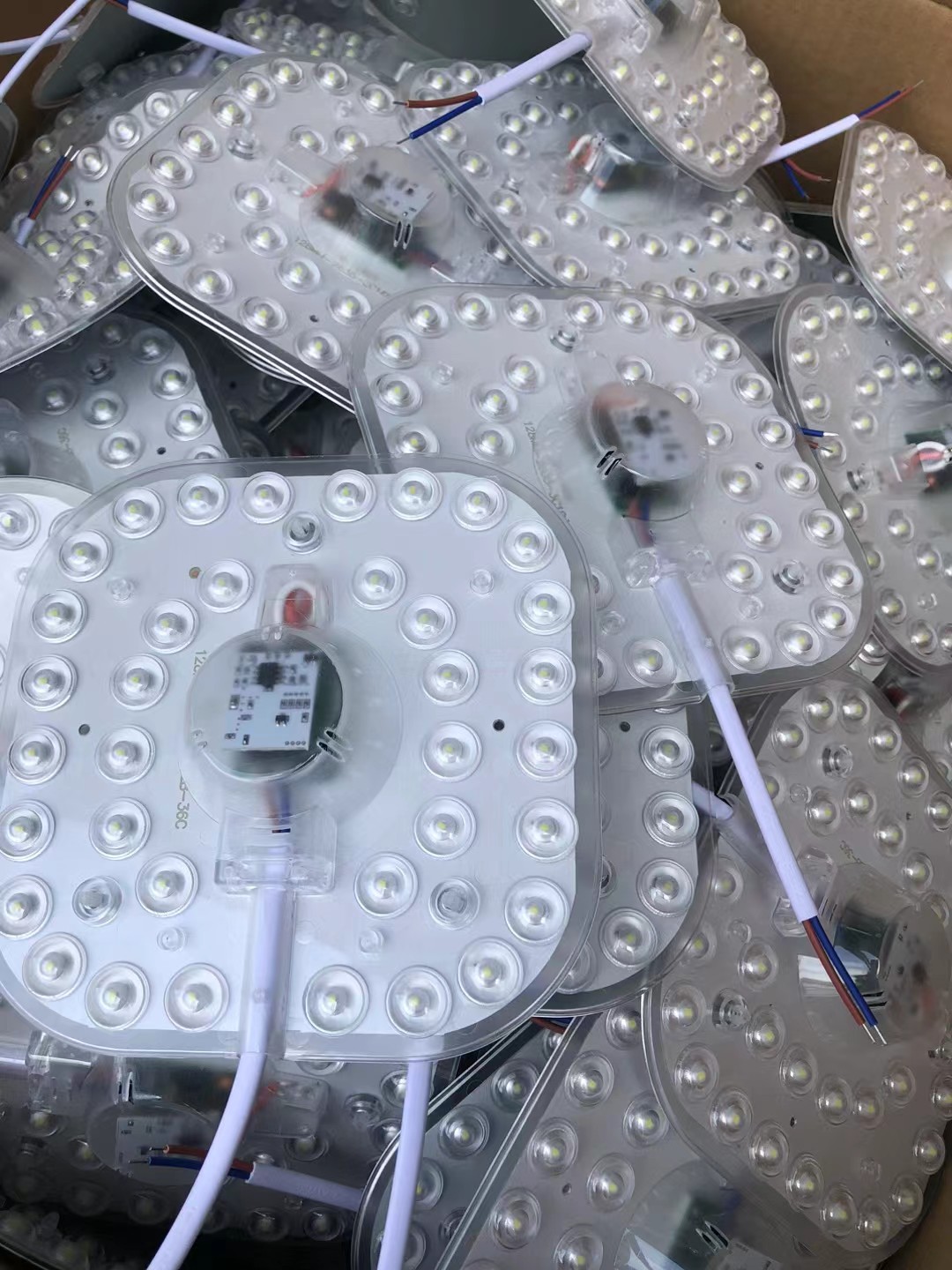

- LED Flush mount ceiling lights (118)

- LED Recessed ceiling lights-> (178)

- Dimmable led bulb phase dimming-> (399)

- PWM dimming LED bulb DC Dimmer-> (187)

- MOSFET LED dimmer wall switch (34)

- 0-10V Dimmer Dimmable LED lights (42)

- DALI track rail conductor rail (19)

- DALI compatible light fittings (79)

- DMX512 Decoder dmx controller (32)

- LDR PIR RF DC dimmer LED driver-> (62)

- Automatic light bulbs (26)

- WiFi Zigbee Tuya mesh Smart LED (31)

- Smart curtain opener homekit (6)

- WiFi smart plug socket switch (24)

- NEMA Plugs Sockets Receptacles (5)

- LED bulbs for cars and boats-> (307)

- UV led bulb UV-A UVB UV-C (50)

- LED transformer Dimmable driver (64)

- LED lights RGB color controller (4)

- RGBW LED Strip Pixel LED Strip (46)

- LED RGB colorful lights (130)

- LED Exterior lighting fixtures (18)

- Exterior lighting landscape LED (29)

- LED aluminum bar lights (7)

- LED sodium light replacement (49)

- Commercial lighting Exhibit lamp (3)

- Photographing indoor lighting (16)

- LED Pin Spot Track Lights (63)

- LED Plant Grow Lights (47)

- LED Industrial machine lights (26)

- LED Underwater LED Fountain lamp (60)

- LED Pool Light bulb 12V 24V (62)

- Portable Welding Gun Spot Welder (9)

- OEM, wholesale LED lights-> (246)

- Outdoor products LED headlamp (25)

- Home Accents Holiday LED Lights (15)

- LED modules for backlight (8)

- Custom led lighting solutions (47)

- Lamp Socket 3 way socket (31)

- lamp cap lamp holder base (13)

- RFID ESL Smart Digital shelf tag (9)

- Solar powered battery charging (25)

- Aviation boat Navigation Light (8)

- Car Kits for Cell phone Laptop (23)

- Push button led instrument light (59)

- RC Helicopters (3)

- Household item Red Light Therapy (5)

- Light Meter/ illuminance Meter (3)

- Borescope Endoscope Snake Scope (13)

- Objectives Lenses phone lens set (25)

- LED surgical shadowless lamp (3)

- Extra cost-Tariffs-Express post (6)

- All Products ...

Information

More Information

Who's Online

There currently are 51 guests online.

Your IP Address is: 216.73.216.149

Copyright © 2025 www.ledlightbulb.net/. Powered by Zen Cart